WATER SOFTENER

A water softener is effective in removing some of the most common contaminants found in private wells or town water supplying homes in Bellingham. The main contaminants are iron & manganese as well as the hard water minerals magnesium and calcium. Small amounts of these minerals can have large affects on your home’s water quality. The EPA maximum allowable level for iron as a secondary contaminant is .3 parts per million and for manganese is .05 parts per million. As you can see, these are very small amounts, but their affects can create quite an impact. Water softening will be very effective if you have hard water, iron or manganese in your well water. Up-flow versus down-flow water softeners are more effective, particularly if there are elevated levels of iron or manganese in your water.

Water Softener & Sediment Filter

A water softener is effective in removing dissolved forms of iron & manganese and hard water minerals. To remove particulate iron or manganese, a cartridge filter with proper micron rating will be effective. Depending on the specific situation, this could require a series of filters with different size micron ratings to handle heavier levels in the water. Selecting the appropriate micron rating and style of filter can be determined by a water treatment professional based on water test results and other symptoms. For more information on Iron and Manganese in water, see our published articles in Water Technology Magazine at the following link: http://publications/.

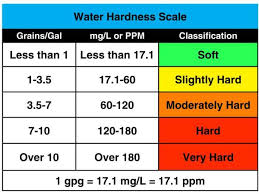

Compare your test results to this chart:

OTHER AFFECTS OF IRON, MANGANESE & HARD WATER

Hard water affects include corrosion and scaling inside pipes, as well as major staining throughout the home’s showers, bathtubs, and sinks. Hard water is also notorious for destroying hot water heaters way ahead of their useful life (scale build-up inside hot water heaters can insulate the temperature sensor inside the tank causing them to work much harder to bring the temperature up to the set level).

Iron and manganese can create pipe and appliance corrosion, as well as orange, rusty or black/brown staining in laundry, showers and other fixtures.

Dissolved Iron Staining

WATER TESTING

Having a water test performed is an important first step in the process of improving your water quality. For more on water testing, see the link at http://water-testing/. For more on water softening, see How Softeners Work.